Analysis of the Relationship between APS Thermal Spray Parameters of Ni5Al Particles and Coating Characteristics

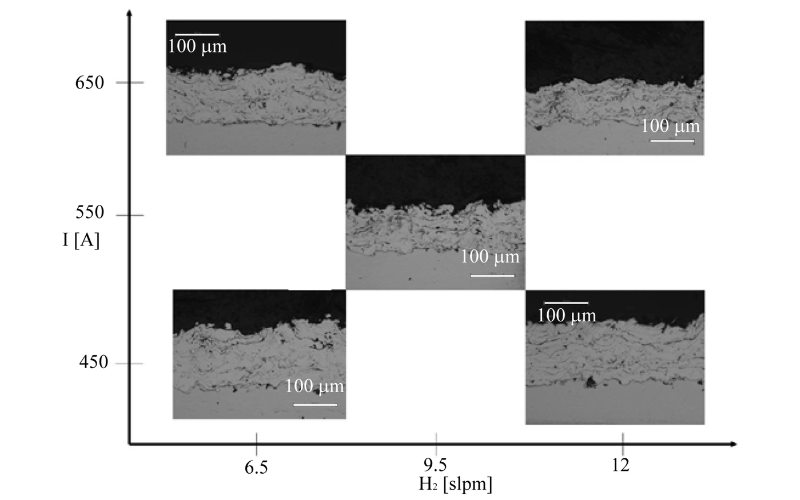

The strength and characteristics of a coating are defined by the impact and temperature of the individual molten particles, as well as by the state of the surface to be coated. The parameters selected for thermal spraying determine the parameters of the particles in flight: temperature and velocity. These parameters can be determined by measuring the thermal radiation intensity of the particles in flight. The parameters that define the thermal spray are the mass flow rate, the intensity, and the 𝐻2 flow rate in the gas mixture to be propelled into the spray gun. On the other hand, the strength of the coating obtained can be estimated using its hardness and adhesion. In this study, a design of the experiments is developed to determine the relationships between the operating parameters and the parameters characterising the particles. From this design, the results obtained are analysed. The experimental results confirmed the direct relationship between intensity and particle temperature, consistent with the relationship between intensity and energy generated in the arc in the spray device. The velocities followed a similar relationship. Increasing the proportion of 𝐻2 in the feed gas led to a higher heat transfer to the particles, consistent with the information found in the literature. A similar effect was detected for the velocity. The adhesion and hardness increase with the speed and temperature of the particle in flight, which is related to a more efficient spatter-flattening process. The applied procedure provides an efficient methodology for the development of useful surfaces for the optimisation of thermal spraying processes.

Key words: APS; thermal spray, fluid mechanics, coating

Originally published at Coatings 2023, 13(9)

By Adrián Fernández Roiz, José Andrés Moreno, Guillermo Jorde Cerezo and Joaquín Solano