Microstructure and Adhesion Strength of Ti Cold Spray Splats: The Influence of Powder Morphology

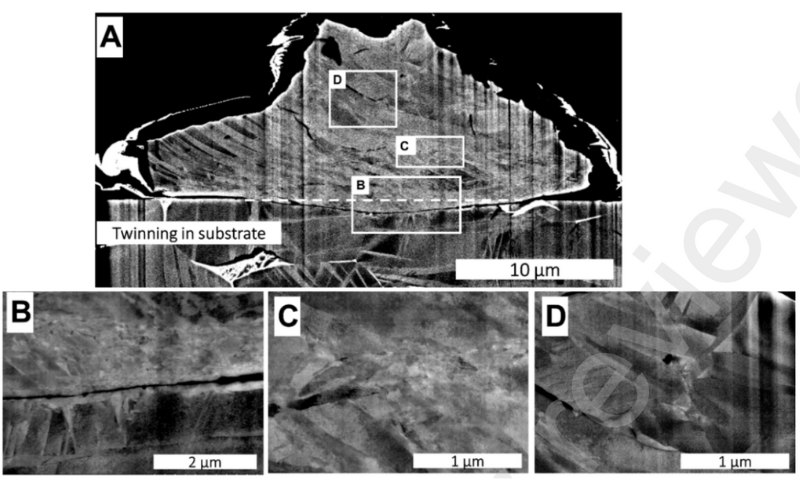

Cold spraying is an emerging additive manufacturing technology that can be used to repair metals and alloys. The adhesion strength and microstructure of the splats influence the mechanical and tribological properties of parts repaired by cold spray. The present study examined the adhesion strength and microstructure of commercially pure Grade 4 Ti splats. The influence of initial powder morphology on adhesion strength and microstructure of splats was studied for cold sprayed samples prepared at two different gas preheat temperatures of 800 and 950 ˚C. The adhesion strength of the single splats was measured using splat adhesion testing. Microstructural analysis of splats was performed using electron channeling contrast imaging on splat cross-sections. Our findings show that increasing gas temperature led to a higher adhesion strength for both morphologies. At both gas preheat temperatures, splats of angular morphology particles displayed a higher adhesion strength than irregular particles. This was due to the higher degree of deformation and microstructural refinement that angular splats showed. Irregular particles, although being impacted on the substrate at higher velocities, displayed a lower extent of grain refinement. The initial pores in irregular morphologies were retained in splats, especially away from the splat/coating interface. These findings contribute to our understanding of cold spray technology and its potential applications in repairing metals and alloys by highlighting the importance of powder morphology and gas preheat temperature in achieving optimal adhesion strength and microstructure in cold-sprayed parts.

Key words: adhesion, Microstructure, Cold spray, Splats, Morphology, Ti

By A. Alidokht Sima, and Chromik Richard