Improving Coating Repeatability by Parameter Adaptation Through Process Monitoring, Gaussian Process Models and Kalman Filters

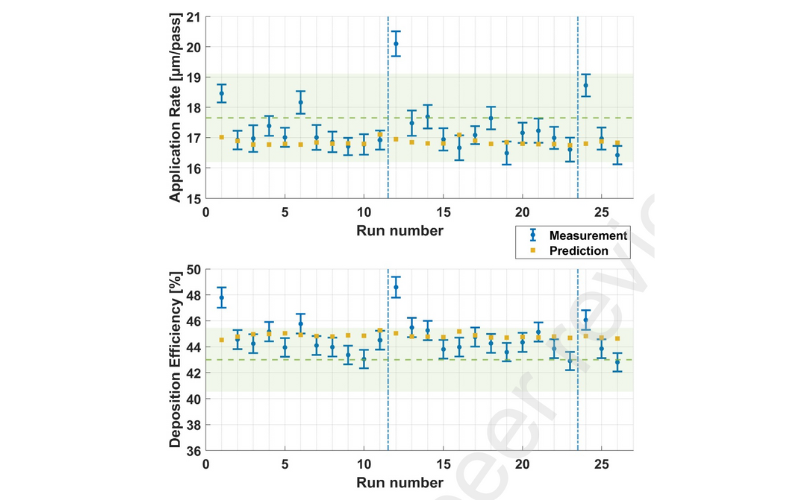

Producing coatings of repeatable quality is a crucial objective of any coating process, including atmospheric thermal spraying (APS). With the existing output regulation methods used in APS, it is common to see significant variations in the coating characteristics of sequentially coated parts, which are insufficient to meet the ever‑stricter requirements of new coating applications. Therefore, this paper suggests a novel process output regulation method that improves repeatability of coating characteristics by combining advanced monitoring solutions and machine learning approaches. It uses Gaussian process models and Kalman filters to adjust process input parameters between sequentially coated parts based on feedback of gun voltage, ensemble particles’ temperatures, deposition efficiency, and application rate. The method enables not only compensation of process degradation but more generally minimizes the long‑term differences in the process state between different coating runs by using a system‑state‑aware process model to track the temporal changes of the coating system. The developed method was tested in an industrial environment and compared to the most commonly used approach in APS of spraying sequential parts with the same process input parameters, and to the approach of adjusting the process inputs based on the gun voltage. The developed method produced coatings with smaller variation and closer to the target compared to the other two approaches.

Key words: output regulation, repeatability, process monitoring, process modelling, machine learning, atmospheric plasma spraying

By Hudomalj, Uroš and Guidetti, Xavier and Weiss, Lukas and Nabavi, Majid and Wegener, Konrad