Leave nothing to chance

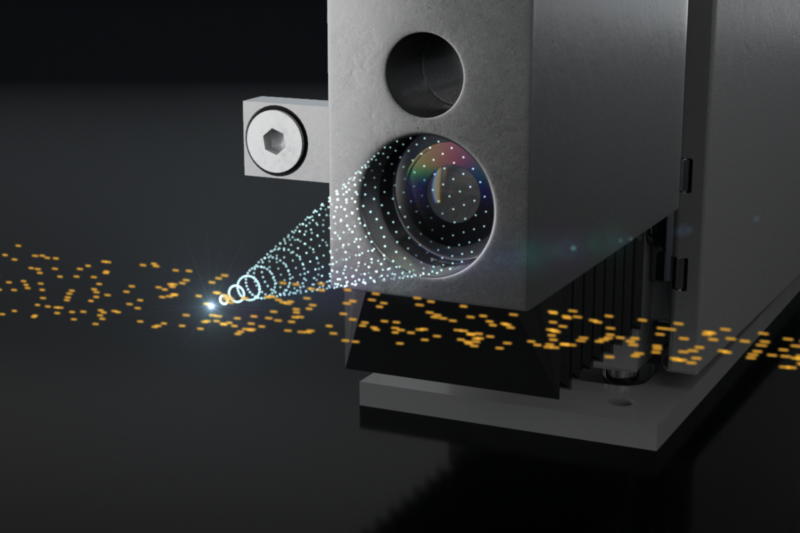

The DPV Evolution is the industry’s standard for understanding the details of in-flight particle dynamics. It measures the velocity, temperature and size of individual particles.

Talk to an expertA stellar track record

Invented in 1990, the concept of the DPV Evolution is simple. It uses an advanced optical system to detect individual particles within the spray plume. Thanks to proprietary-designed masks and numerical processing, it retrieves the temperature, the velocity and the relative size of each individual particle.

More than 1,000 papers have been published on DPV results and today, it is still the absolute best method for advanced research in the field of in-flight characterization of sprayed particles.

Individual particle temperature

Individual particle velocity

Individual particle size

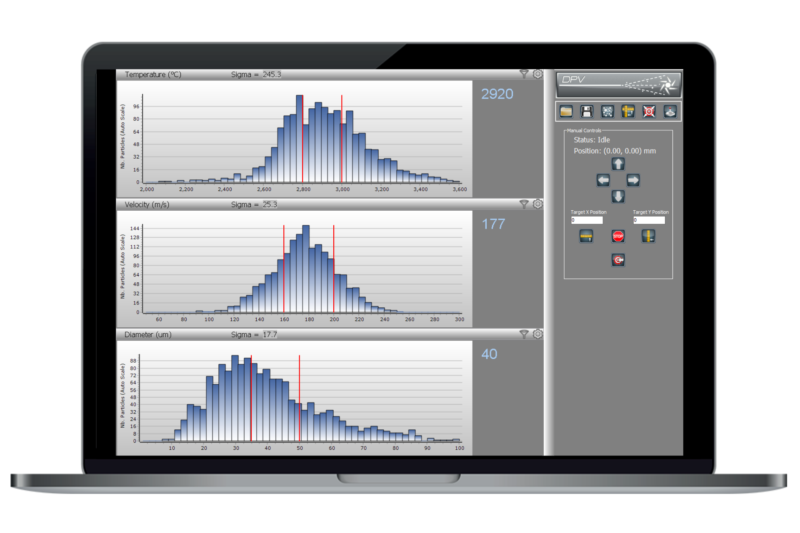

Temperature distribution

Velocity distribution

Size distribution

The DPV Evolution advantage

The best accuracy in the industry

The DPV Evolution’s main edge is that it has a very small sampling volume within the spray plume. This sampling volume is spectrally and spatially filtered, which produces a distinctive signal when a particle travels through this volume. Although thousands of particles cross the DPV sampling zone every second, only the ones that generate the profile of an individual particle are collected in the measurement. That’s why the reliability of the data produced by the DPV is still unquestioned after 30 years. It is still being used to verify other particle detection technologies, such as PIV and DOPPLER systems.

Advanced correlations

One of the main advantages researchers appreciate is the ability to correlate measurements with one another. Due, once more, to the single particle detection, the distribution of velocities and temperatures can be displayed as a function of the particle size or volume. We call these volumetric distributions and they are key to seeing the true velocity of the particles that actually build your coating. Using the DPV Evolution distributions, operators can optimize the spray parameters to achieve the desired coating properties or deposition efficiencies.

In this image, the operator has chosen to display secondary distributions for temperature and velocity (in green) for the particles identified by the green rectangle, which corresponds to the lower end of the size distribution. As one should expect, these particles have a bias towards higher temperatures and velocities.

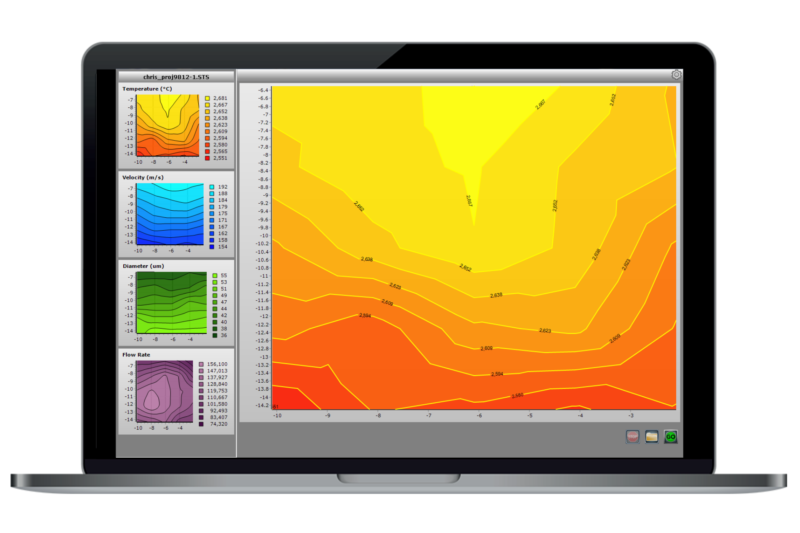

Cross-sectional mapping

The DPV Evolution comes standard with an X-Y scanning unit. The unit can automatically centre the gauge on the spray plume. It also provides complete spatial mapping of your velocity, temperature and size distributions at the exact plane where your substrate will be later. For processes with radial injections, it’s critical to know where the heavy or light particles are heading and what their temperature is once they impact the surface.

Easy to use

Compared to other single particle detection technologies, the DPV Evolution is by far the easiest to install and operate. The typical signal produced by a single isolated particle is easily understood by any DPV operator, so it’s simple to adjust the instrument’s processing filters when approaching a new material. Also, the velocity, temperature and size distributions lend valuable insight about the justness of the instrument’s settings. Any truncated distribution will stand out and the operator can easily adjust the system accordingly.

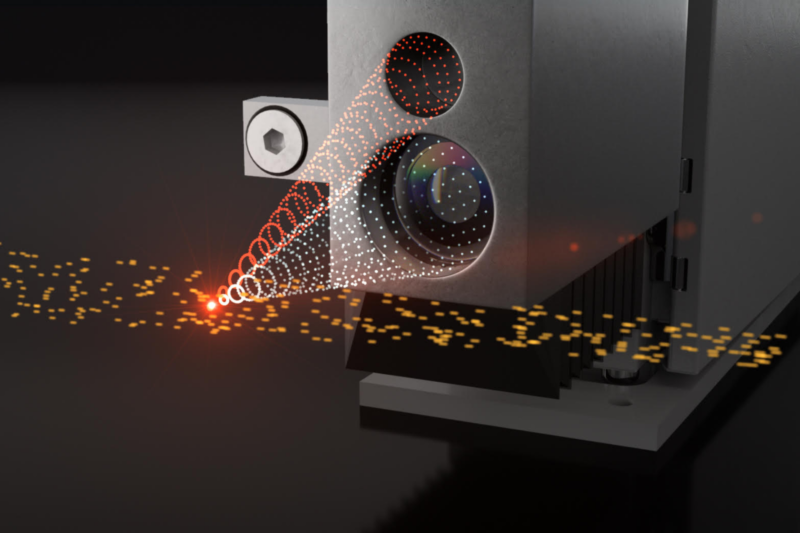

CPS option

With the Cold Particle Sensor option (CPS), the DPV Evolution can detect and measure cold particles. It is commonly used for colder processes such as HVAF or any cold spray process.

Cold particle velocity

Cold particle size

Cold particle velocity and size distribution

CPS : Cold Particle Sensor

The DPV Evolution collects the light naturally emitted by hot particles. For temperatures below 1000 °C, depending on the material, it becomes harder to track particles. In these cases, the distributions will appear severely truncated.

The CPS option is a laser-based illumination that allows all particles down to a few microns in size to be visualized. Combining the velocity and size distribution with the CPS option, the DPV Evolution operator can complete the measurements that were lacking for cold particles.

Technical specifications - DPV Evolution

Measurements ranges

Particle temperature

≥1050 °C, depending on process parameters, at 3% precision

≥1922 °F, depending on process parameters, at 3% precision

Particle velocity

Low speed configuration: 5-400 m/s at 2% precision

High speed configuration: 400-1200 m/s at 2% precision

Low speed configuration: 16-1300 f/s at 2% precision

High speed configuration:1300-3900 f/s at 2% precision

Particle diameter

10-300 µm, depending on process parameters

0.39-11 µin, depending on process

Spray plume width and position (Plumespector option)

0.2 mm precision

0.008 in. precision

Measurement volume information

Working distance

100 mm

3.93 in.

Temperature & velocity measurement volume

Low speed configuration: 0.15 mm³ at 5 mm depth of field

High speed configuration: 0.43 mm³ at 5 mm depth of field

Low speed configuration: 0.0000091 in.³ at 0.2 in. depth of field

High speed configuration: 0.000026 in.³ at 0.2 in. depth of field

XY Scanning travel

100 mm x 100 mm

3.93 in. x 3.93 in.

Dimensions and weight

Sensor head

152 mm x 367 mm x 706 mm

6 in. x 14.5 in. x 27.8 in.

Controller

580 mm x 770 mm x 305 mm

22.8 in. x 30.3 in. x 12 in.

Calibration module

304 mm x 200 mm x 340 mm

12 in. x 7.9 in. x 13.4 in.

Total weight

56.4 kg

124.3 lbs

Plant supplies

Power requirements

120 - 240 VAC, 50-60 Hz 5A

120 - 240 VAC, 50-60 Hz 5A

Air supply

1.35-2 bar of clean dry compressed air

20-30 psi of clean dry compressed air

Product options

Cps-2000

For cold particles characterization

Plumespector

For spray plume cross-sectional intensity profile

Substrate temperature pyrometer

-18 to 525 °C

0 to 975 °F

Interested in the DPV Evolution?

Leave your details so our experts can contact you.

Our team will answer all your questions and suggest the best solution for your needs.