多快才算够快?

Coldspray Meter 是从事冷喷涂工艺的研究人员和生产管理人员的理想工具。它有助于验证流体动力学模型、优化喷嘴、开发和优化喷涂参数、最大限度地提高沉积效率,并在生产运行过程中监控过程。其直观的触摸屏用户界面使其易于集成到日常操作中。数据以 CSV 文件的形式提供,可以通过以太网或 USB 闪存驱动器轻松访问

速度和粒度分布

尺寸与速度的相关性

通量(进给率)

Coldspray Meter 的优点

单粒子检测

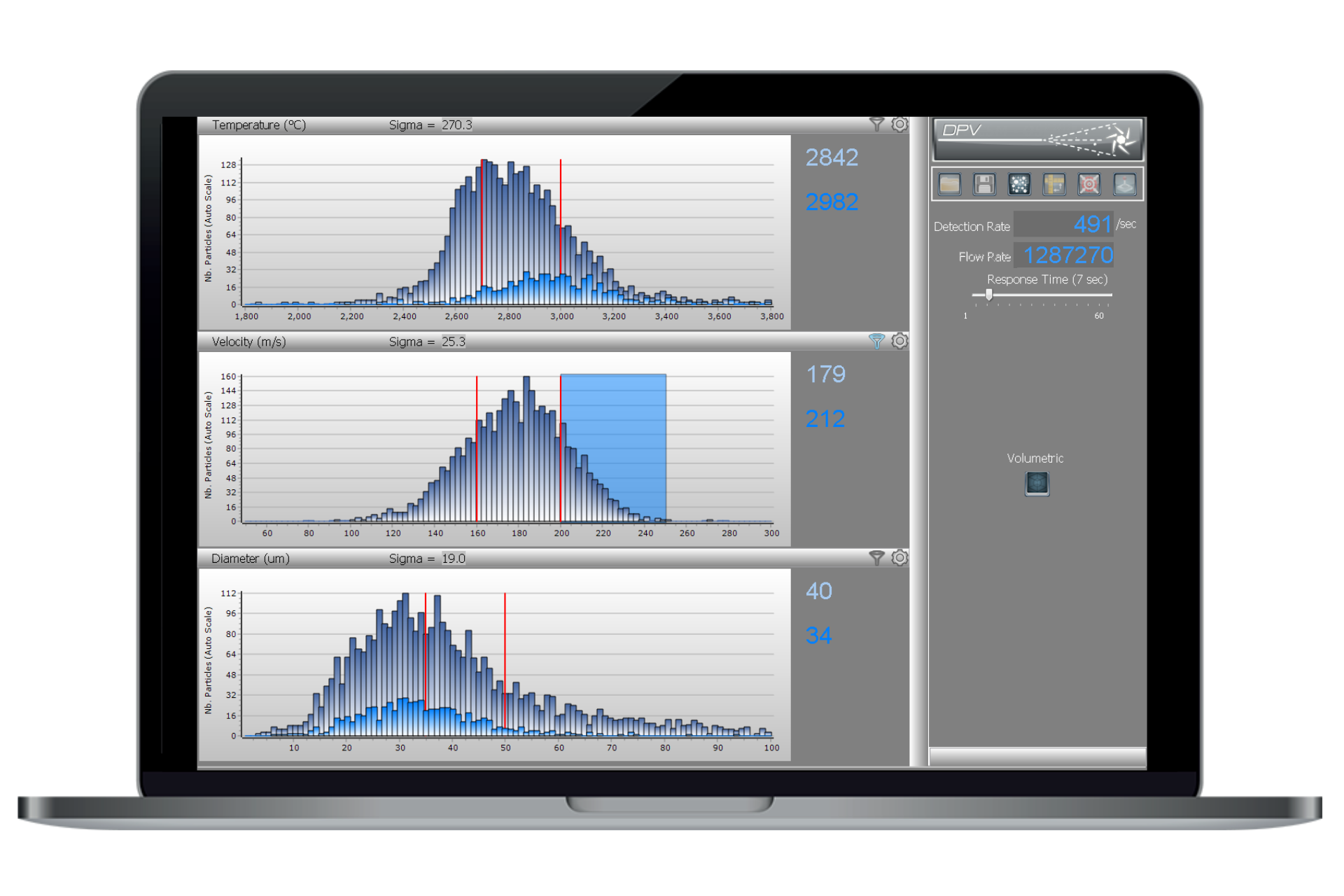

Coldspray Meter 基于 DPV 技术,因此它一次测量一个粒子,速度高达每秒 300 个粒子。DPV 粒子检测所固有的高级过滤层可以由操作员进行平衡,以确保最大的检测率并避免误报

相关性

计算穿过 Coldspray Meter 取样体积的每个颗粒的速度和尺寸测量值。这样就有可能看到,与较小的粒子相比,较大的粒子是否有明显的速度差异。这些相关性是验证喷涂模型和优化喷嘴的关键

分配

由于单个粒子检测,Coldspray Meter 实时提供完整的速度和尺寸分布。速度曲线也可以显示在 x 轴上的体积比例,以阐明沉积效率

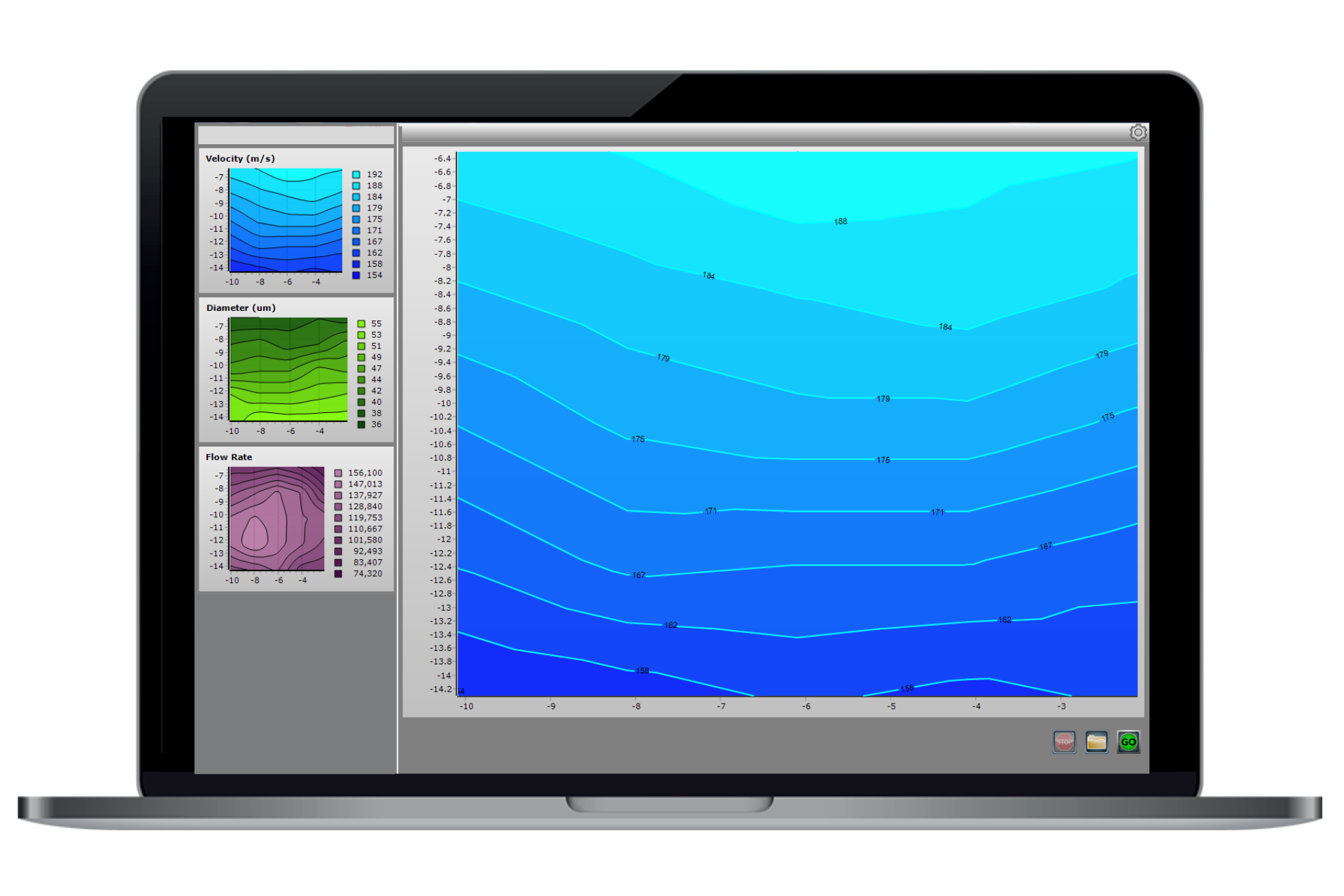

横截面轮廓

与 DPV 一样,Coldspray Meter 的采样体积非常小,这是单个粒子检测的关键。该仪器还配备了一个 X-Y 扫描设备,具有先进的功能,如自动定心和速度和尺寸分布的二维映射

技术规格

测量范围

颗粒速度

精度为 2% 时为400-1200 米/秒

**可选**:低速配置:5-400 米/秒

精度为 2% 时为1300-3900 英尺/秒

**可选**:低速配置:16-1300 英尺/秒

颗粒直径

10-300 微米,取决于工艺参数

0.39-11 微英寸,取决于工艺参数

测量体积信息

工作距离

100 毫米

3.93 英寸

温度和速度测量体积

5 毫米景深时为 0.43 立方毫米

**可选 **:低速配置:0.15 立方毫米

0.2 英寸景深时为 0.000026 立方英寸

**可选 **:低速配置:0.0000092 立方英寸

XY 扫描行程

50 毫米 × 50 毫米

2 英寸 x 2 英寸

尺寸和重量

扫描模块

152 毫米 x 300 毫米 x 615 毫米

6 英寸 x 11.8 英寸 x 24.2 英寸

控制器

580 毫米 x 770 毫米 x 305毫米

22.8 英寸 x 30.3 英寸 x 12英寸

总重量

49.5 千克

109.1 磅

工厂安装条件

电源要求

20-240 VAC,50-60 HZ 5A

气体供给

1.35-2 bar 清洁干燥压缩空气

20-30 psi 清洁干燥压缩空气

激光特性

类型

第四级

波长

790 纳米

标称功率

3.3 W

最大功率密度

6.5 W/平方厘米

42 W/平方英寸

对 Coldspray Meter 感兴趣吗?

请留下您的详细信息,以便我们的专家与您联系

我们的团队将回答您的所有问题,并根据您的需求提出最佳解决方案