辉煌的业绩记录

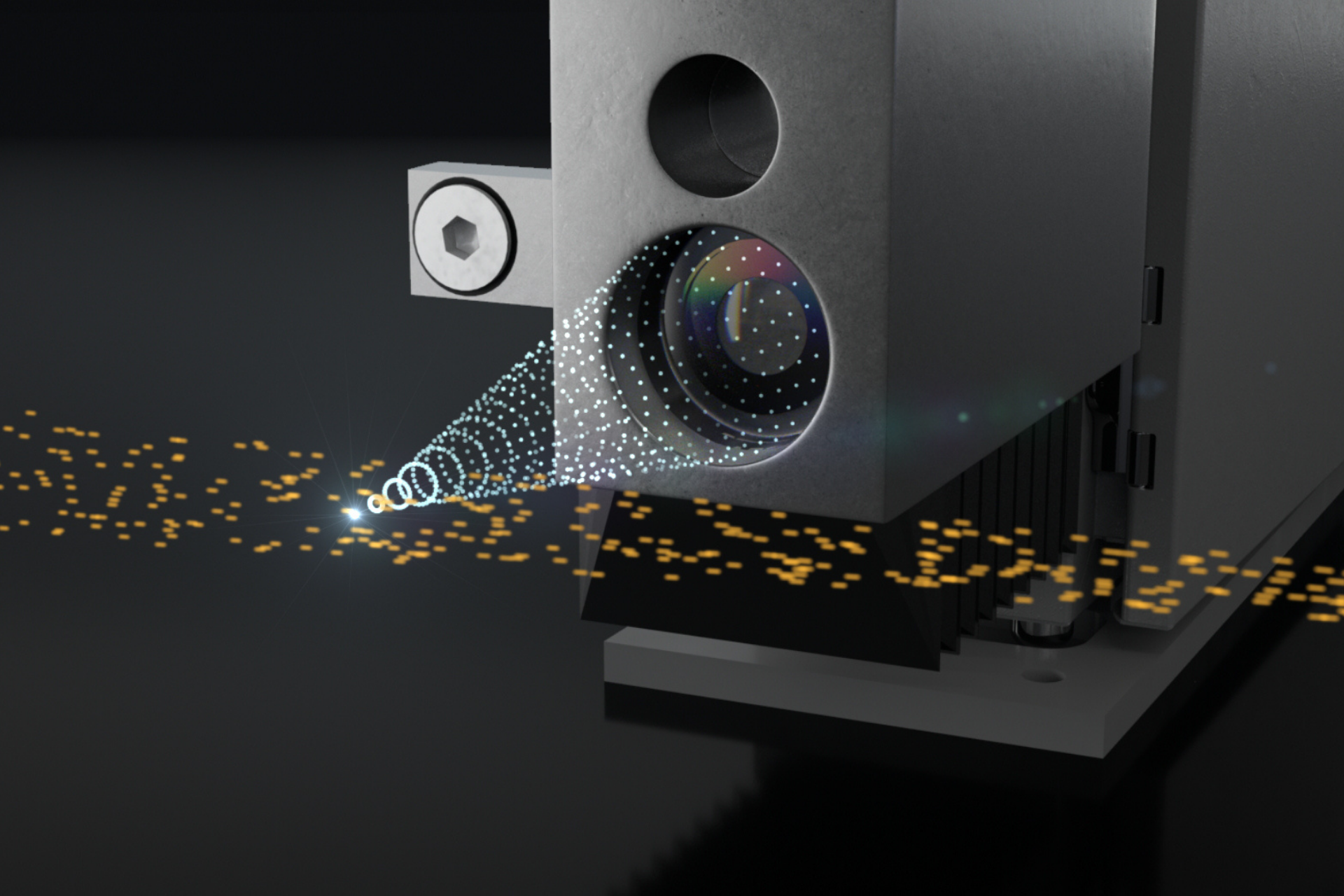

DPV Evolution 于 1990 年发明,概念很简单。它使用先进的光学系统来探测喷涂焰流中的单个粒子。得益于专利设计的掩模和数值处理,它能够检索每个粒子的温度、速度和相对大小。

关于 DPV 的研究成果已经发表了 1000 多篇论文,至今仍是喷涂粒子飞行特性研究领域最先进的方法。

单个粒子温度

单个粒子速度

单个粒子尺寸

温度分布

速度分布

尺寸分布

DPV Evolution 优势

业内最精确

DPV 发展的主要优势在于它在喷涂焰流中的取样体积非常小。该采样体积经过光谱和空间滤波,当粒子穿过该体积时,产生独特的信号。每秒有数千个粒子穿过 DPV 采样区,在测量过程中收集生成单个粒子轮廓的粒子。这就是为什么 30 年后,DPV 产生的数据的可靠性仍然毫无疑问。它仍被用于验证其它粒子检测技术,如 PIV 和 DOPPLER 系统。

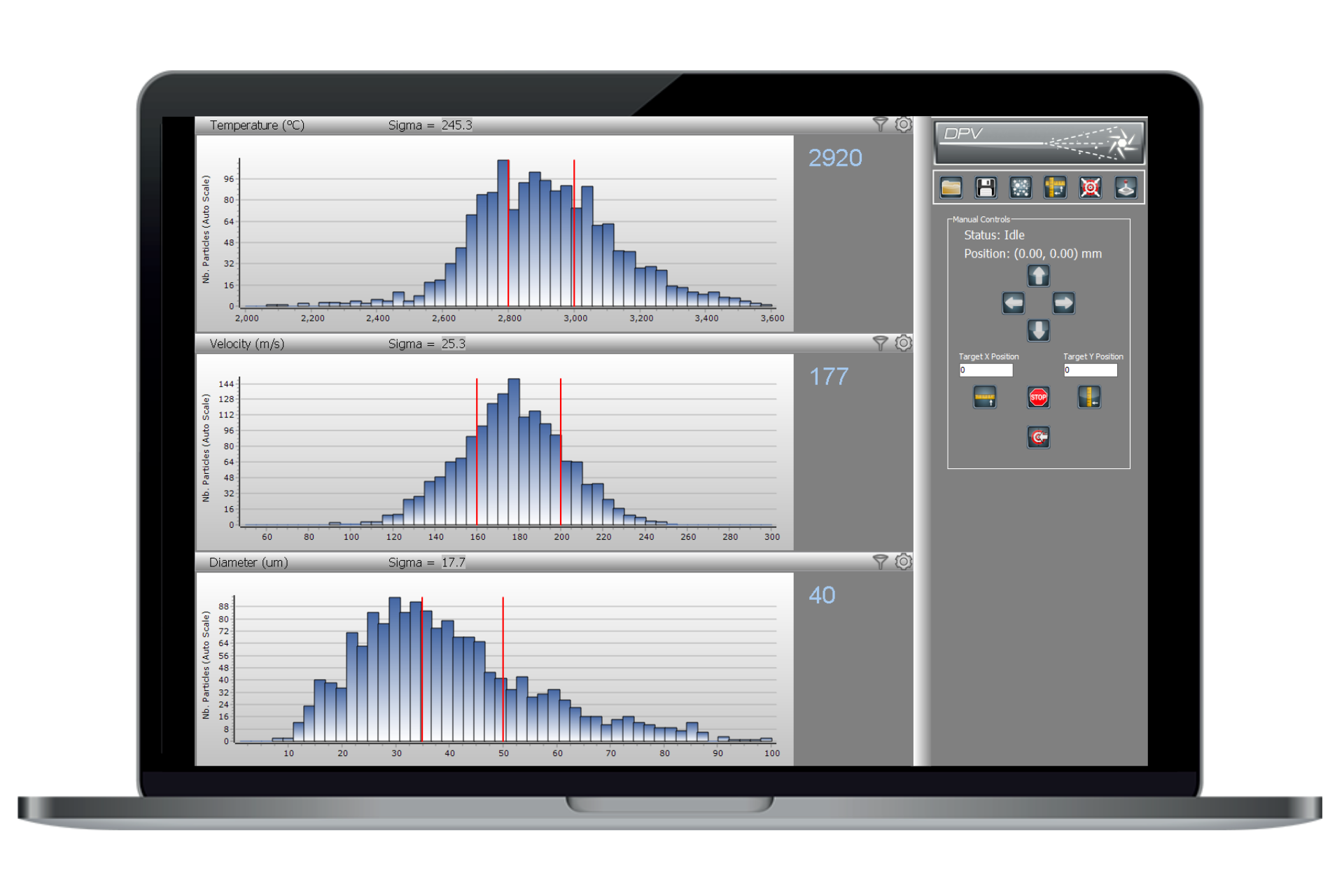

高级相关性

研究人员所欣赏的一个主要优点是能够将测量值相互关联起来。由于单粒子检测,速度和温度的分布可以显示为粒子大小或体积的函数。我们称之为体积分布,它们是观察实际形成涂层的粒子真实速度的关键。利用 DPV Evolution 分布,操作者可以优化喷涂参数以获得所需的涂层性能或沉积效率。

在此图像中,操作员选择显示由绿色矩形标识的粒子的温度和速度的二级分布(绿色),该矩形对应于尺寸分布的下端。正如人们所预料的,这些粒子倾向于更高的温度和速度。

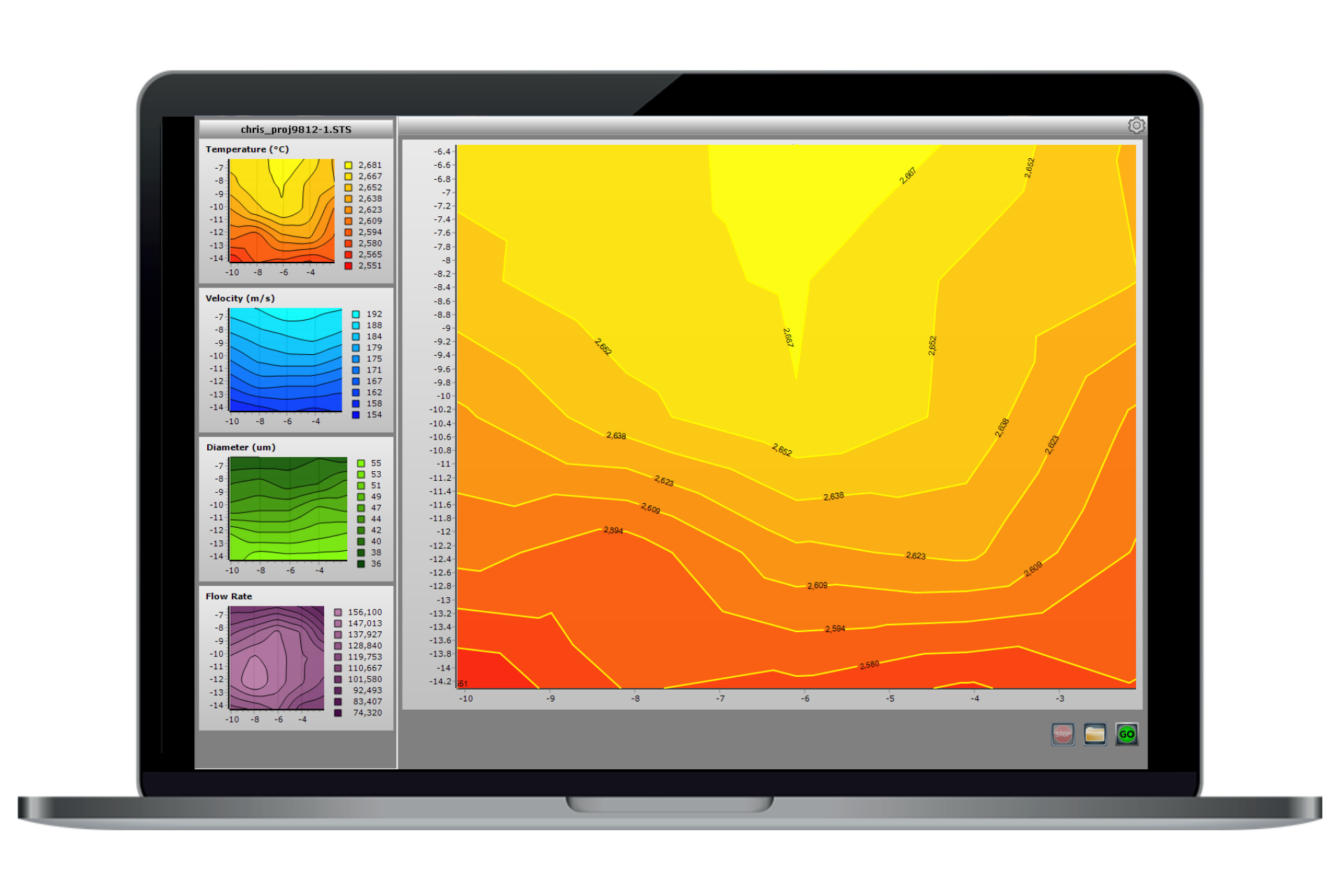

横断面扫描

DPV Evolution 标配有 X-Y 扫描单元。 该装置可以自动将测量点计置于喷涂焰流的中心。它还提供了您的速度、温度和尺寸分布的完整空间映射,这些映射位于您的基板稍后所在的确切平面上。对于采用径向注入的喷涂工艺,了解重粒子或轻粒子的前进方向以及它们撞击表面后的温度是至关重要的。

易于使用

与其它单粒子检测技术相比,DPV Evolution 是迄今为止最容易安装和操作的技术。任何 DPV 操作员都很容易理解单个孤立粒子产生的典型信号,因此在处理新材料时调整仪器的处理过滤器很简单。此外,速度、温度和尺寸分布也为仪器设置的合理性提供了宝贵的见解。任何截断的分布都会明显突出,操作员可以轻松地相应地调整系统。

CPS 可选项

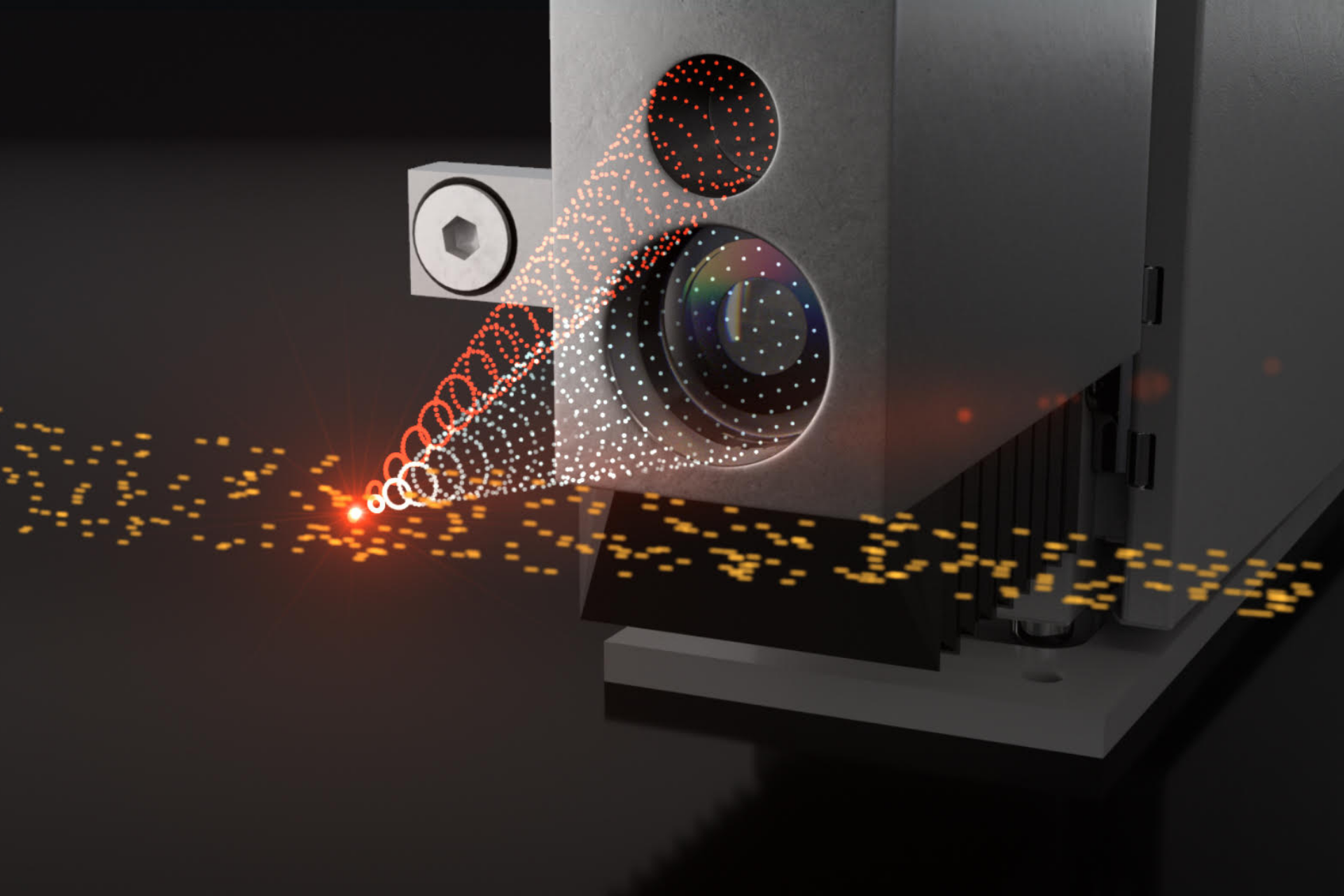

使用冷喷涂粒子传感器可选项(CPS),DPV Evolution 可以检测和测量冷喷涂粒子。它通常用于较冷的工艺,如超音速氧燃料火焰喷涂(HVAF)或任何冷喷涂工艺。

冷喷涂粒子速度

冷喷涂粒子粒径

冷喷涂粒子速度和粒径分布

CPS:冷喷涂粒子传感器

DPV Evolution 收集热粒子自然发出的光。对于低于 1000°C 的温度,根据材料的不同,跟踪粒子变得更加困难。在这些情况下,分布将出现严重截断。

CPS 选项是一种基于激光的照明,允许所有尺寸小于几微米的粒子被可视化。结合速度和尺寸分布与CPS 可选项,DPV Evolution 操作员可以完成冷喷涂粒子所缺乏的测量。

技术规格 - DPV Evolution

测量范围

颗粒温度

精度 3% 时为 ≥1050 °C,取决于尺寸和发射率

精度 3% 时为 ≥1922℉,取决于尺寸和发射率

颗粒速度

精度 2% 时为:低速配置:5-400 米/秒,高速配置:400-1200 米/秒

精度 2% 时为:低速配置:16-1300 英尺/秒,高速配置:1300-3900 英尺/秒

颗粒直径

5-300 微米,取决于工艺参数

0.2-11.8 微英寸,取决于工艺参数

测量区域信息

温度和速度测量体积

低速配置:5 毫米景深时为 0.15 立方毫米

高速配置:5 毫米景深时为 0.43 立方毫米

低速配置:0.2 英寸景深时为 9.1 e-6 立方英寸

高速配置:0.2 英寸景深时为 2.6 e-5 立方英寸

工作距离

100 毫米

4 英寸

XY 扫描行程

100 毫米 × 100 毫米

4 英寸 x 4 英寸

产品选项

CPS 激光

用于冷颗粒特征描述的 3.3W 四级激光器

用于 DPV 的 Accuraspray 4.0

通过相机分析来表征喷涂焰流的几何形状

基材红外测温探头

0 °C 至 500 °C

32 °F 至 932 °F

使用用于 DPV 选件的 Acurraspray 4.0 的测量范围

喷涂焰流宽度和位置

±0.6 毫米精度

±0.02 英寸精度

焰流角度

0.2 度精度

焰流强度

5% 精确度

工厂安装条件

电源要求

120/230 VAC Auto-Switch 50/60 Hz 4.9/2.7A

气体供给

1.35-2 bar

20-30 psi

尺寸和重量

扫描单元

706 毫米 x 367 毫米 x 152 毫米,13 公斤

27.8 英寸 x 14.5 英寸 x 6 英寸,28.7 磅

控制器

770 毫米 x 580 毫米 x 305 毫米,40 公斤

30.3 英寸 x 22.8 英寸 x 12 英寸,88.2 磅

校准单元

200 毫米 x 304 毫米 x 340 毫米,8 公斤

7.9 英寸 x 12 英寸 x 13.4 英寸,17.6 磅

运输(产品+包装箱)

87 厘米 x 71 厘米 x 95 厘米,150公斤

34.3 英寸 x 28 英寸 x 37.4 英寸,330.7 磅

您想进一步了解 DPV Evolution 吗?

请留下您的详细信息,我们的专家会与您联系。

我们的团队将回答您的所有问题,并根据您的需求提出最佳解决方案。