等离子体成分对钇稳定氧化锆(8YSZ)隔热涂层(TBC)热循环性能的影响

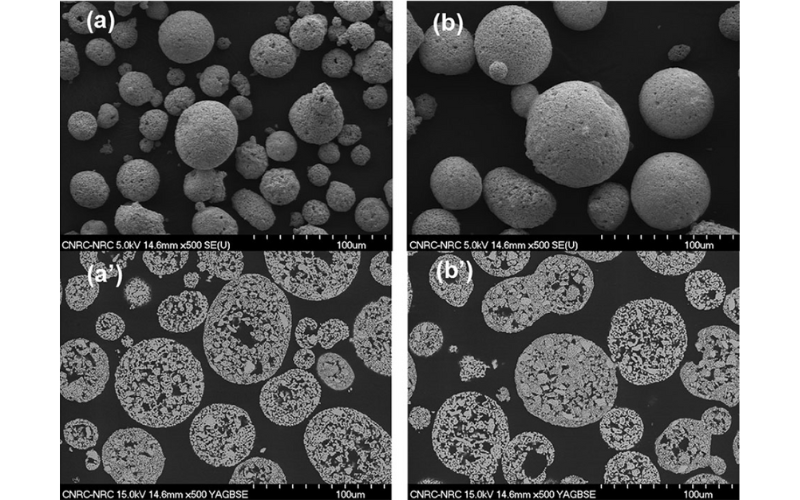

在燃气涡轮发动机的燃烧室中,ZrO2-8wt.%Y2O3(YSZ)TBC 通常是通过传统火炬使用基于 Ar-/H2 的等离子体进行空气等离子喷涂 (APS)。或者,也可以使用 N2/H2 等离子体,这样有可能提高整体沉积效率 (DE),从而减少高价值原料粉末的消耗。此外,通过提高沉积效率,还可以缩短喷涂时间,从而为降低生产成本做出贡献。在这项工作中,使用 Metco 9MB 传统割炬,用氩气和二氧化氮等离子体与不同的 YSZ 粉末制备了 TBC。与氩基等离子体相比,使用 N2 基等离子体可获得更高的颗粒温度和更低的颗粒速度值。在氩基和 N2 基等离子体中测得的 DE 值分别为 41-43% 和 53-60%。这表明 DE 增加了约 40%。使用两种不同等离子体生产的涂层显示出同等的孔隙率水平 ~ 11-13%。平均而言,N2 基 LD-B YSZ TBC 的热导率值最低。在熔炉循环测试中,用 N2 等离子体制备的 TBC 性能优于用 Ar 等离子体制备的 TBC,也超过了工业 APS TBC 基准。

关键词:APS、Ar-H2、沉积效率 (DE)、N2-H2、TBC、热导率、热循环 (FCT)、YSZ

最初发表于《热喷涂技术期刊》(2021 年 1 月 20 日,第 30 卷,第 59-68 页,2021 年)

作者:Bruno Guerreiro、Rogerio S. Lima、Nicholas Curry、Matthias Leitner、Karl Korner