空气等离子喷涂隔热涂层的预氧化和 TGO 生长行为

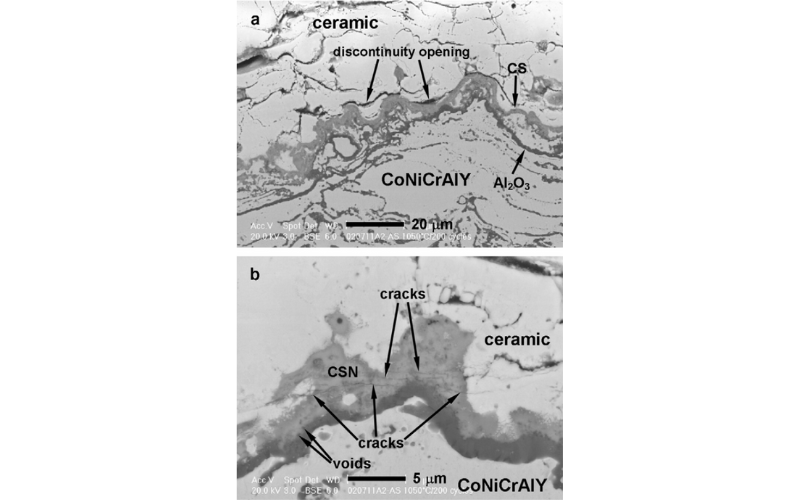

在热障涂层(TBC)系统中,氧化环境中形成的尖晶石和氧化镍被认为不利于 TBC 在高温条件下的耐久性。本研究表明,在带有 Co-32Ni-21Cr-8Al-0.5Y(重量百分比)结合层的空气等离子喷涂(APS)TBC 中,低压氧气环境中的预氧化处理可通过促进陶瓷面层/结合层界面上 Al2O3 层的形成来抑制有害氧化物的形成。热长性氧化物(TGO)层的形成通常表现出类似高温蠕变的三阶段生长现象。预氧化处理可降低生长速度,延长稳态生长阶段,从而提高耐久性。TBC 中的裂纹扩展是通过陶瓷表层中预先存在的不连续性的开裂和生长进行的,并得到与 TGO 相关的裂纹成核和生长的辅助。热循环过程中的裂纹扩展似乎受 TGO 生长的控制,最大裂纹长度与 TGO 厚度一般呈幂律关系。

关键词: TBC;CoNiCrAlY;预氧化;热循环;TGO 生长;裂纹扩展

最初发表于《表面与涂层技术》(第 202 卷,第 16 期,2008 年 5 月 15 日,第 3787-3796 页)

作者:W.R. Chen、X. Wu、B.R. Marple、R.S. Lima、P.C. Patnaik