HVOF 工艺参数对 TiO2 涂层的影响:使用 DoE 和一阶工艺图的方法

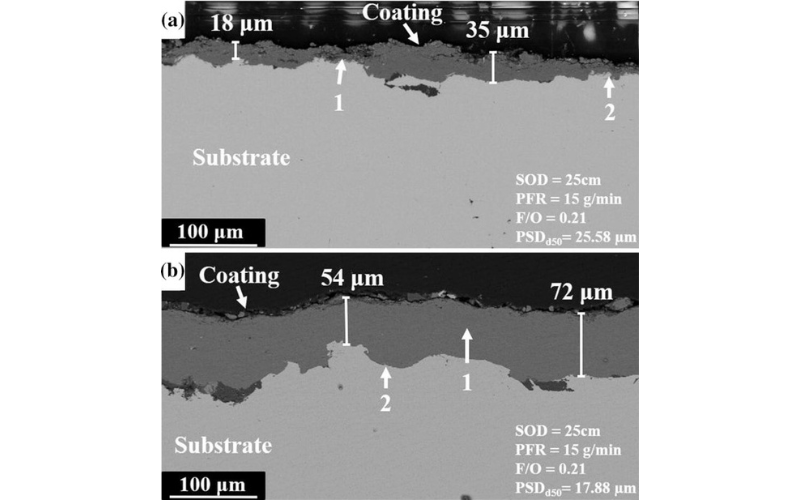

本文对氧化钛涂层的高速氧燃料沉积阶段进行了分析和报告。 对于沉积的第一阶段,使用流程图来评估沉积参数(例如间隔距离(SOD)、送粉速率(PFR)和燃料/氧气比(F/O))对沉积速度和温度的影响。 -飞行粒子。 然后将这些参数与颗粒尺寸分布 (PSD) 相结合,以进一步优化沉积过程,考虑喷雾迹线宽度以及由碎片和非熔融颗粒覆盖的区域作为响应。 此外,通过X射线衍射、拉曼光谱、扫描电子显微镜和纳米压痕获得了单个板片、半和/或非熔融颗粒或涂层的簇的结构、形态和机械特性。 在涂层形成过程中,较低的 PFR 和 F/O 会产生更多的溅射颗粒和更少的半熔融和/或非熔融颗粒簇,而 PSD 会影响喷涂轨迹的宽度。 F/O 和 SOD 较高水平的组合与高百分比的 TiO2 splat 沉积有关。 最后,所提出的方法可以获得金红石相含量较高、平均厚度为 65 µm 的致密 TiO2 涂层。

最初发表于《热喷涂技术杂志》(第 28 卷,第 1160–1172 页,2019 年)

作者:G. A. Clavijo-Mejía、D. G. Espinosa-Arbeláez、J. A. Hermann-Muñoz、A. L. Giraldo-Betancur 和 J. Muñoz-Saldaña