工程 HVOF 喷涂 Cr3C2-NiCr 涂层: 颗粒形态和喷涂参数对显微结构、性能和高温磨损性能的影响

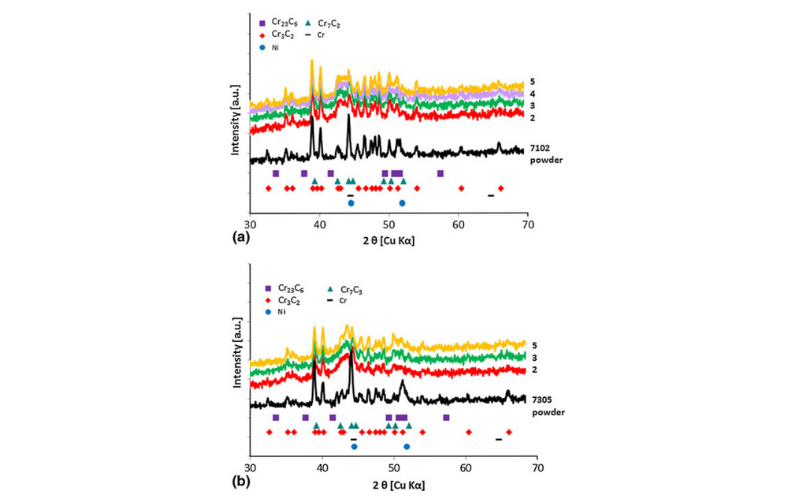

以碳化铬为基材的热喷涂涂层广泛用于高温磨损应用(典型温度范围为 540 至 900 °C)。在这些温度下的极端环境中,有几种现象会使涂层降解、氧化并改变其微观结构,从而影响其磨损性能。虽然可以很容易地想到,高温暴露后的 Cr3C2-NiCr 涂层微观结构演变将取决于喷涂时的微观结构和喷涂参数,但这方面的研究却很少。本研究旨在更好地了解喷涂参数对高温操作后碳化铬涂层微观结构和高温滑动磨损性能的影响。通过 X 射线衍射和扫描电子显微镜,对两种形态的 Cr3C2-NiCr 粉末在飞行中颗粒温度和速度值窗口下产生的不同涂层的微观结构进行了表征。在 800 °C 下进行了滑动磨损,磨损行为与喷涂参数和涂层微观结构相关。此外,还测量了滑动磨损前后涂层的维氏硬度(300 gf)。

关键词:碳化铬、高温磨损、HVOF、显微结构、滑动磨损测试、喷雾参数

原文发表于《热喷涂技术期刊》(2012 年 11 月 10 日,第 22 卷,第 280-289 页,2013 年)

作者:Dominique Poirier、Jean-Gabriel Legoux、Rogerio S. Lima