悬浮液闪蒸雾化在悬浮液等离子喷涂中的应用

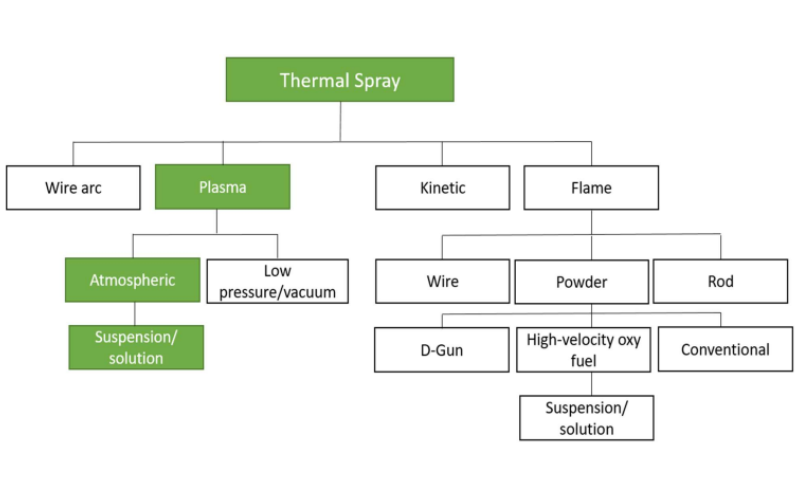

悬浮液等离子喷涂 (SPS) 是一种用于沉积亚微米和纳米级颗粒的热喷涂技术。通过将悬浮液暴露于等离子射流中,液体会蒸发。然后,颗粒会熔化并被引导到等离子射流中,撞击基材并形成涂层。与其他热喷涂技术相比,SPS 的固体进料速率和沉积效率较低。增加悬浮液中的颗粒浓度可以提高原料的沉积速率,但高粘度和喷嘴堵塞是问题。

为了解决这些问题,本研究探索了闪蒸雾化 (FBA) 作为 SPS 中高固体浓度(高达 70 wt.%)的新型喷射方法。FBA 利用热力学不稳定性来分解液体射流。当过热悬浮液通过喷嘴加速并且其压力降至饱和压力以下时,就会发生快速沸腾。蒸汽气泡在液体射流内膨胀,导致其分裂成更小的部分。FBA 可应用于燃油喷射、海水淡化和制药等各种行业。主要目的是使用 FBA 将高固体悬浮液注入等离子流以形成 SPS 涂层。

SPS 中的悬浮液注入可以是轴向的,也可以是径向的。在轴向注入中,碎片发生在火炬内部,而在径向注入中,悬浮液从火炬外部注入等离子流中。传统的径向注入方法包括喷雾雾化(产生碎裂液滴)和机械注入(产生连续喷射)。本研究将用 FBA 制成的涂层与用机械注入制成的涂层进行了比较,评估了微观结构、每次沉积重量、沉积效率和涂层厚度。结果表明这些参数都有所改善。

水和乙醇是常见的悬浮溶剂。水基悬浮液面临雾化和抗蒸发性的挑战,影响涂层性能。FBA 可以通过降低过热状态下的粘度和表面张力来改善碎片并防止堵塞。研究了高固体浓度和等离子功率对涂层微观结构、单次厚度、单次沉积重量和沉积效率的影响,结果表明,使用 70 wt.% 悬浮液和高功率喷灯可实现高固体沉积的致密涂层微观结构。

最初发表为康考迪亚大学博士论文。

作者:Saeid Amrollahybiouki