颗粒温度和速度对高速富氧燃料(HVOF)喷涂纳米结构二氧化钛涂层的微观结构和力学行为的影响

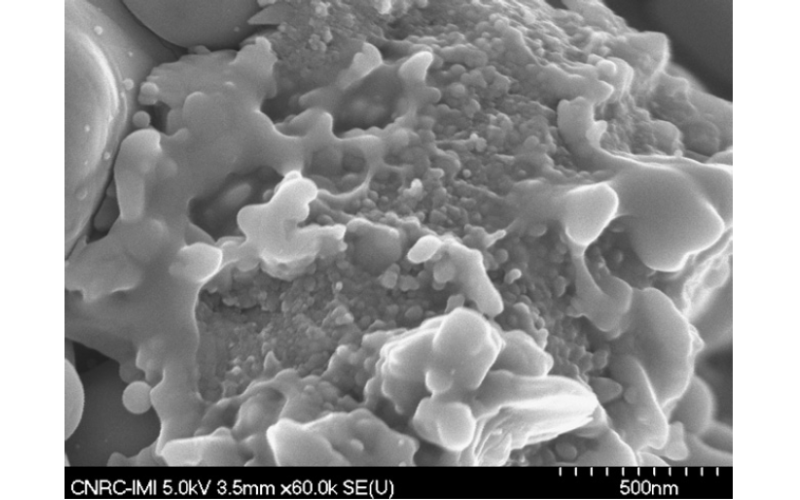

纳米结构的二氧化钛原料粉末通过高速富氧燃料(HVOF)喷涂沉积在 Ti-6Al-4V 基底上。利用飞行中粒子诊断技术,采用了不同的粒子温度和速度,以揭示它们对涂层微观结构和机械性能的影响。在加工条件(即飞行中粒子的温度和速度)和由此产生的涂层微观结构特征和性能(如相组成、维氏显微硬度和阿尔门条的偏转(残余应力))之间,观察到一系列线性关系。与文献中的其他陶瓷热喷涂涂层相比,该涂层具有较高的粘结强度。这项研究提供了通过 HVOF 喷射加工纳米结构陶瓷粉末的不同层次的信息,为 HVOF 喷射纳米结构二氧化钛涂层在生物医学领域和其他需要卓越机械性能的学科中的开发和应用提供了可能性。

关键字:热喷涂、高速全氧燃烧(HVOF)、飞行中粒子诊断、纳米二氧化钛(TiO2)、微观结构、结合强度

最初发表于《材料加工技术期刊》(第 198 卷,第 1-3 期,2008 年 3 月 3 日,第 426-435 页)

作者:M. Gaona, R.S. Lima, B.R. Marple