优化的 HVOF 二氧化钛涂层

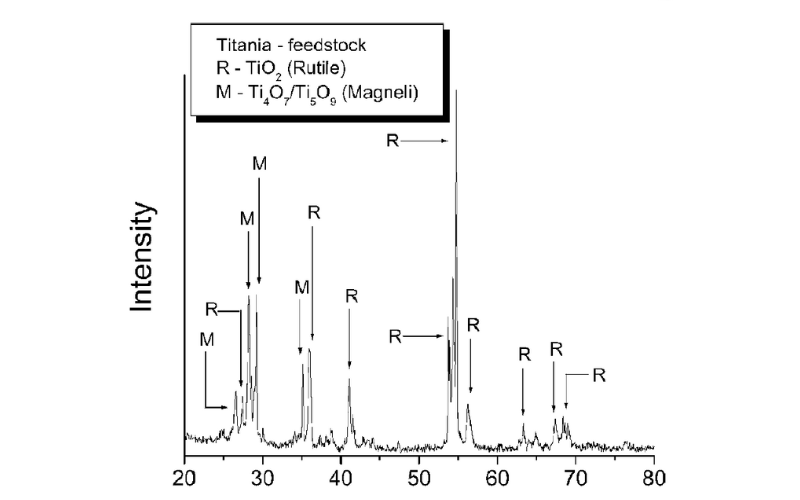

针对二氧化钛 (TiO2) 原料测试了一系列喷雾参数,并测量了每种设置组合的飞行颗粒温度。选择产生最高颗粒温度的参数集来生产涂层以供进一步研究和分析。通过此参数设置,大多数喷涂颗粒的温度(至少表面上)高于二氧化钛的熔点。使用努普技术和维氏硬度测量来评估这些 HVOF 喷涂二氧化钛涂层的横截面和顶表面的硬度 (H)、弹性模量 (E) 和弹性指数(H/E 比)。通过威布尔统计分析弹性模量和硬度值的分布。分别使用扫描电子显微镜(SEM)和X射线衍射(XRD)分析评估涂层的微观结构和相组成。通过图像分析确定孔隙率水平。观察到涂层均匀且非常致密,由金红石作为主要相组成。优化的喷涂条件允许生产厚涂层(∼740 µm),使用阿尔门试片测量表明该涂层处于残余压应力状态。

关键词: HVOF, 压痕, 微观结构定制, 二氧化钛, 威布尔模量

最初发表于《热喷涂技术杂志》(第 12 卷,第 360-369 页,2003 年)

作者:R. S. Lima,B. R. Marple