高速富氧喷涂纳米结构和传统金属陶瓷涂层的工艺温度/速度-硬度-磨损关系

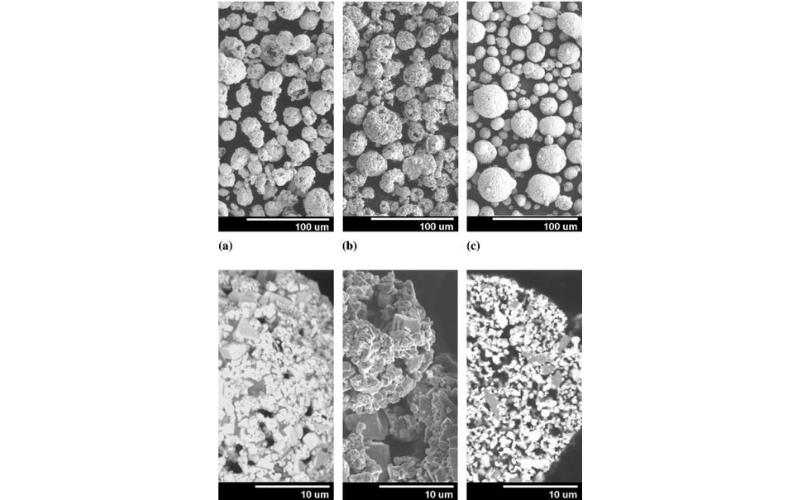

对 WC-12Co 进行了高速全氧燃烧(HVOF)喷涂,使用的原料是 WC 相,其中 WC 相主要在微米尺寸范围内(传统型)或经过设计含有大量纳米颗粒(多模式型)。我们使用了三种不同的 HVOF 系统和多种喷涂参数设置来研究飞行中颗粒特性对涂层性能的影响。确定了颗粒温度的工艺窗口,以生产出具有最高耐干磨性能的涂层。虽然使用含有纳米级 WC 相的原料能生产出更硬的涂层,但性能最好的传统涂层和多模态涂层的耐磨性差别不大。不过,由于沉积效率更高、加工窗口更大,使用多模态原料可能会带来好处。

关键词:高速全氧燃烧、纳米结构、工艺性能关系、WC-12Co

最初发表于《热喷涂技术期刊》(2005 年 3 月,第 14 卷,第 67-76 页,2005 年)

作者:B. R. Marple、R. S. Lima