悬浮式高速氧燃料(S-HVOF)热喷涂中的径向喷射石墨烯纳米片摩擦学研究

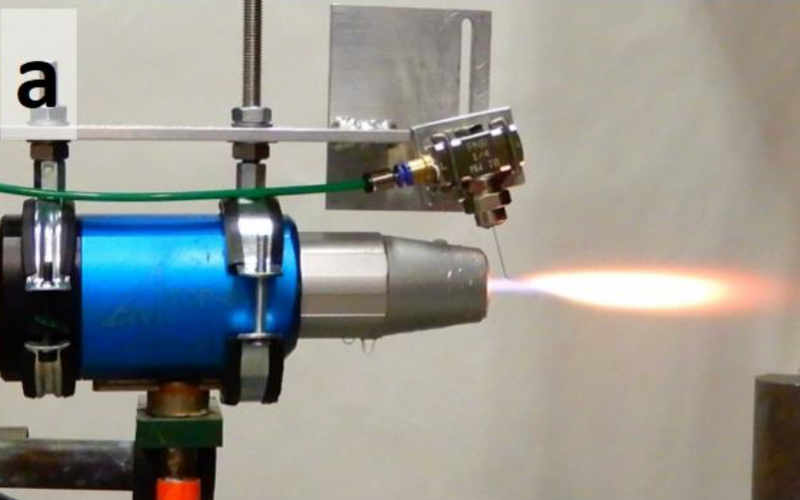

摩擦是任何由运动机械零件组成的设备提高能效的一个主要问题,会影响设备的耐用性和可靠性。石墨烯纳米颗粒(GNPs)是减少摩擦和磨损的良好候选材料,而悬浮式高速纯氧燃料(SHVOF)热喷涂是一种很有前途的技术,可实现可扩展的快速沉积,但这种技术会使石墨烯纳米颗粒暴露在过高的热量下。在这项工作中,我们探索了在 SHVOF 热喷涂中径向注入 GNPs 的方法,以减少它们与高温火焰的相互作用,同时还能实现高动量传递和有效沉积。我们使用 Accuraspray 4.0 对不同火焰功率下的高速成像和颗粒温度与速度监测进行了研究,研究了原料喷射参数,如流速、喷射角度和位置。针对氧化铝平衡球的无润滑球对平滑动磨损测试表明,与裸基底相比,摩擦系数降低了 10 倍,降至 0.07。沉积的 GNP 层可实现低摩擦干滑动,从而保护底层基材。透射电子显微镜研究表明,GNPs 在喷涂后仍保持结晶性,而在磨损后则变得非晶化和起皱。这项研究的重点是 GNPs,但也适用于其他对热和氧化敏感的材料,如聚合物、氮化物和二维材料。

关键词:S-HVOF,石墨烯纳米片,径向注入,颗粒温度和速度监测,高速成像,摩擦学,TEM

原文发表于《arXiv》(1909.04940)

作者:F. Venturi,T. Hussain