液滴撞击纹理的溅射沉积应力形成机理

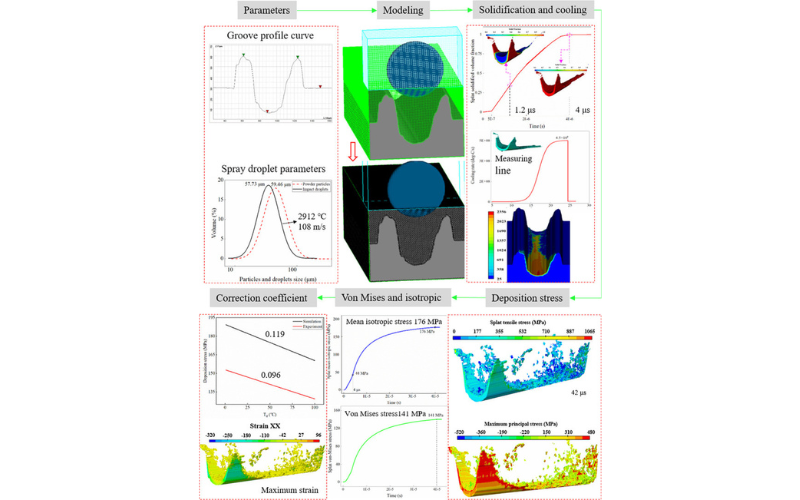

本研究重点是了解等离子喷涂液滴在溅射过程中形成的关键现象——沉积应力,这对于理解等离子喷涂等应用中的涂层应力至关重要。开发了一种新型三维耦合流体-固体和热机械模型,该模型采用流体体积法和有限元法。该模型用于模拟在具有激光纹理凹槽图案的不锈钢基材上等离子喷涂钼液滴时沉积应力的形成。它成功地复制了溅射形成过程的各个阶段,包括冲击、扩散、冷却和凝固,捕捉到了溅射和凹槽壁中温度、应变和应力的变化。通过对平面基材表面上的溅射沉积应力进行 X 射线衍射测量,验证了该模型的准确性。模拟结果表明,在液滴同时扩散和凝固的过程中会产生沉积应力。这种应力归因于淬火和凝固收缩,导致溅射中产生拉应力,键合界面边缘的应力更高。相比之下,槽壁受到压缩应力,在槽中央区域达到峰值。溅射的平均各向同性应力和冯·米塞斯应力分别量化为 176 和 141 MPa。现场曲率测试表明,溅射沉积应力引发的应力松弛导致开裂、屈服和滑移应力减少 24.6%。此外,提出了一个改进的溅射沉积应力理论方程,通过模拟和实验确定了 0.119 的校正系数。开发的模拟模型提供了对溅射沉积应力状态的可靠见解,为优化等离子喷涂工艺提供了有价值的信息,并增强了我们对此类应用中涂层应力的理解。

最初发表于《国际机械科学杂志》(第 266 卷,2024 年 3 月 15 日)

作者:Delong Jia,Dong Zhou, Peng Yi, Chuanwei Zhang, Junru Li, Yankuo Guo, Shengyue Zhang, Yanhui Li