了解二元等离子气体混合物在等离子喷涂中的影响

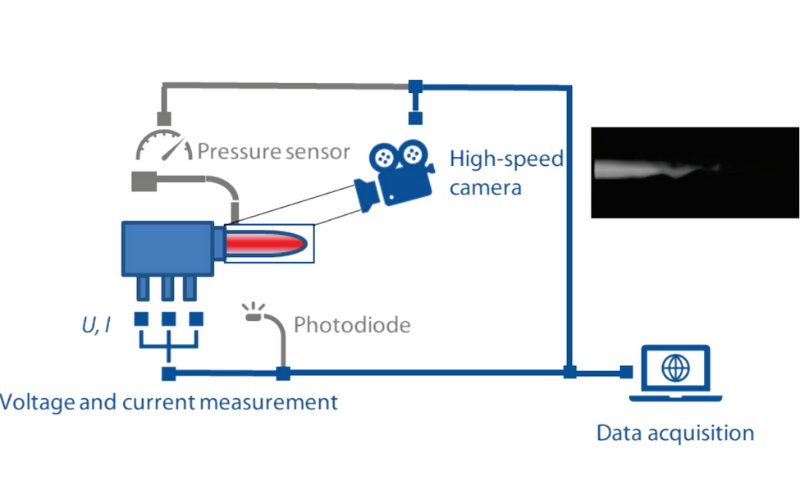

在等离子喷涂中,通常会将 H2 或 N2 添加到主要 Ar 等离子体中,这可以增加比焓、热导率,从而提高工艺效率。本研究的目的是提供具有各种二元气体成分的三阴极等离子炬的工艺特性。使用几种工艺诊断来表征二元等离子气体混合物在等离子喷涂中的影响。使用高速视频分析来捕捉所研究工艺参数的喷射波动。此外,还进行电流和电压测量以进一步补充等离子体诊断。使用粒子诊断系统 DPV-2000 通过测量 Al2O3 原料的粒子飞行特性来确定二元等离子气体混合物的影响。此外,还确定了所研究工艺参数的沉积效率 (DE)。结果表明,在相同的体积流速和电流下,添加 H2 可产生最高的粒子温度,其次是 Ar/N2 混合物和纯 Ar 等离子体。以相反的顺序,纯 Ar 等离子体产生最高的粒子速度。此外,二元混合气体等离子喷涂 Al2O3 涂层的 DE 增加,有可能提高其他陶瓷材料的沉积速率。本研究提供了等离子体和粒子诊断与二元等离子混合气体沉积效率之间的全面相关性。

关键词:氧化铝、沉积效率、气体成分、粒子飞行特性、等离子喷涂、等离子炬

最初发表为 ITSC2024 热喷涂会议论文集在线论文(论文编号:itsc2024p0689,第 689-695 页;共 7 页)

作者:K. Bobzin、H. Heinemann、M. Erck、K. Jasutyn