通过悬浮液和溶液前体热喷涂沉积的 YAG 热障涂层

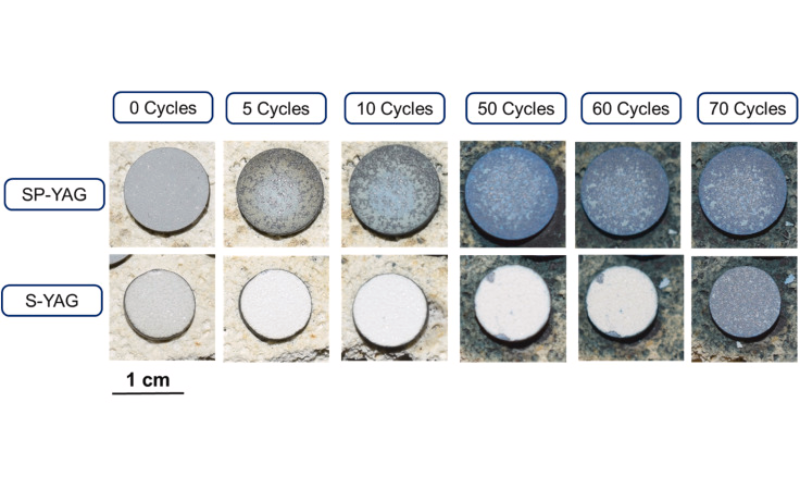

钇铝石榴石(YAG)由于其高温稳定性和更好的耐 CMAS(钙镁铝硅酸盐)性能,是一种很有前途的热障涂层面漆材料。YAG 面漆通过悬浮液和溶液前驱体高速氧燃料 (HVOF) 热喷涂沉积。通过一系列表征技术和热循环测试研究了加工、微观结构和最终性能之间的关系。化学计量溶液前驱体(SP-YAG)喷涂的YAG 面漆的微观结构具有分布的孔隙和片间边界,而悬浮液(S-YAG)喷涂的面漆具有垂直和分支的微裂纹、孔隙、和片间边界。两种喷涂涂层均由非晶相、六方钇铝钙钛矿(YAP)和立方 YAG 组成。在热循环测试中,第10次循环后 SP-YAG 失效达到 20%;而 S-YAG 在第 60 到 70 个循环之间达到了失效标准。SP-YAG 和 S-YAG 面漆均因热循环过程中的热应力而失效。

关键词:YAG相变,新一代 TBC,SHVOF,单溅射

最初发表于 Ceramics International(第 47 卷,第 17 期,2021 年 9 月 1 日,第 23803-23813 页)

作者:T.A. Owoseni,A. Rincon Romero,Z. Pala,F. Venturi,E.H. Lester,D.M. Grant,T. Hussain