使用 N2-H2 和 Ar-H2 等离子体喷涂的钇稳定氧化锆隔热箱: 加工和热处理对涂层性能的影响

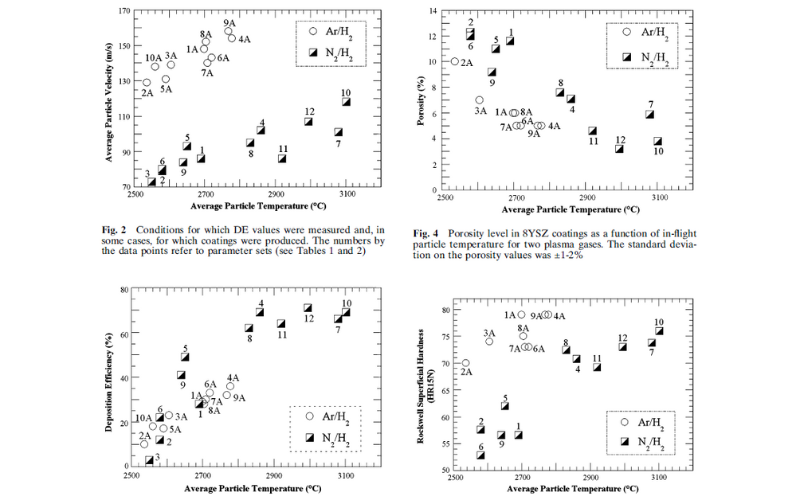

使用 Ar 和 N2 作为主等离子气体生产了热障涂层。对工艺和涂层的各个方面进行了研究。研究发现,使用 N2 可以产生较高的飞行中粒子温度,但粒子速度较低。与氩气相比,使用 N2 可以将沉积效率提高两倍。使用这两种主要气体可以生产出孔隙率、硬度、杨氏模量和热扩散率值相似的涂层。在 1400 °C 下进行热处理时,涂层表现出相似的变化(硬度、刚度和热扩散率增加)。不过,经过 N2 处理的涂层的杨氏模量和热扩散率值往往较低。这些结果表明,在 TBC 沉积过程中使用 N2(而不是 Ar)作为主要等离子气体,在减少粉末消耗和提高生产率方面具有潜在优势。

关键词:沉积效率、弹性特性、飞行中粒子特性、氮氢等离子体、热障涂层、热扩散率、热处理

最初发表于《热喷涂技术期刊》(2007 年 10 月 10 日,第 16 卷,第 791-797 页,(2007 年)

作者:B.R. Marple、R.S. Lima、C. Moreau、S.E. Kruger、L. Xie 和 M. R. Dorfman